Efficiency through innovation

https://www.youtube.com/watch?v=633Vg8FQkPE

|

|

|

Cycle

time reduction in the production of internal threads in hardened materials using a solid carbide circular tapping cutter BGFS from JBO

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

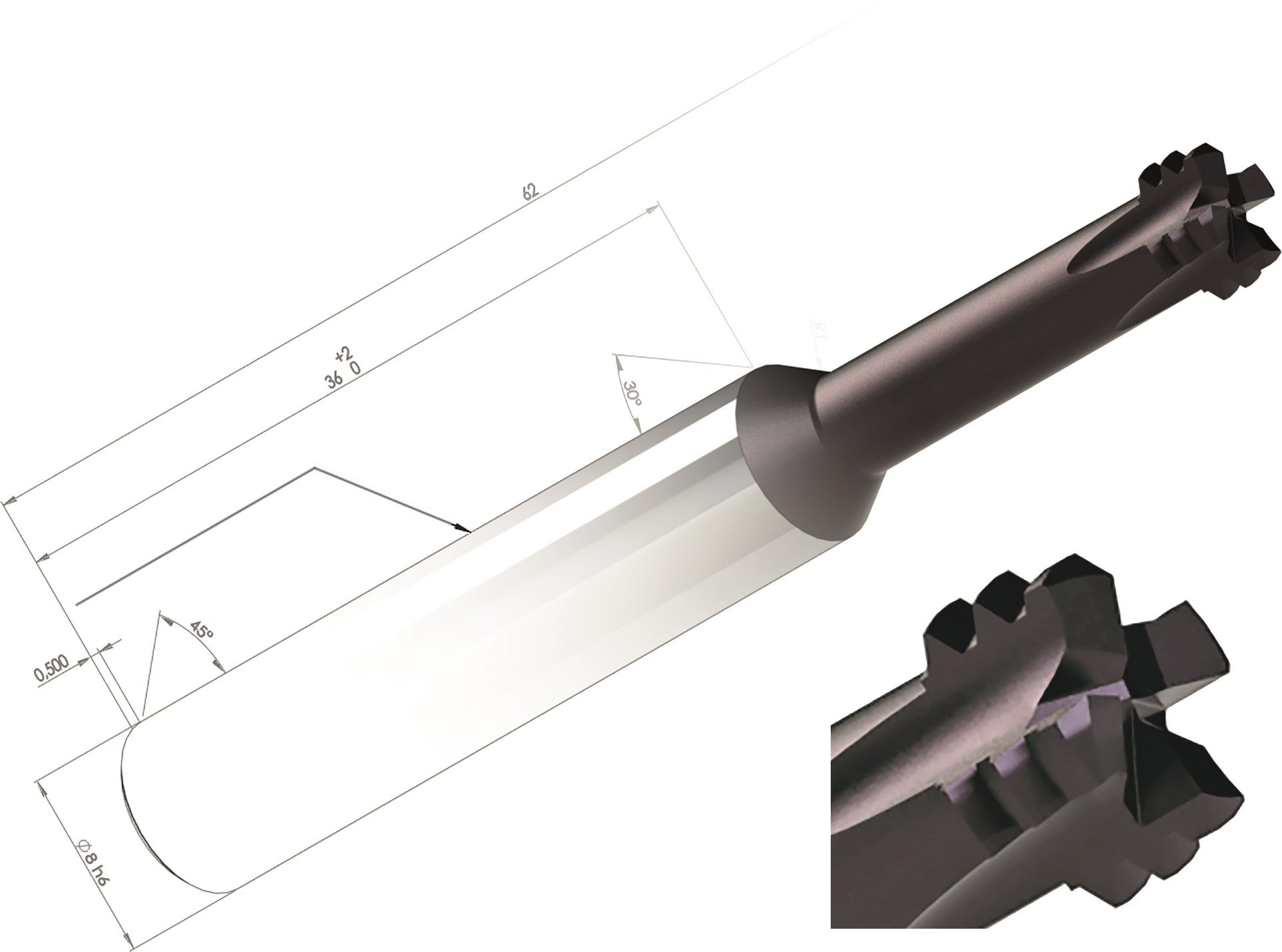

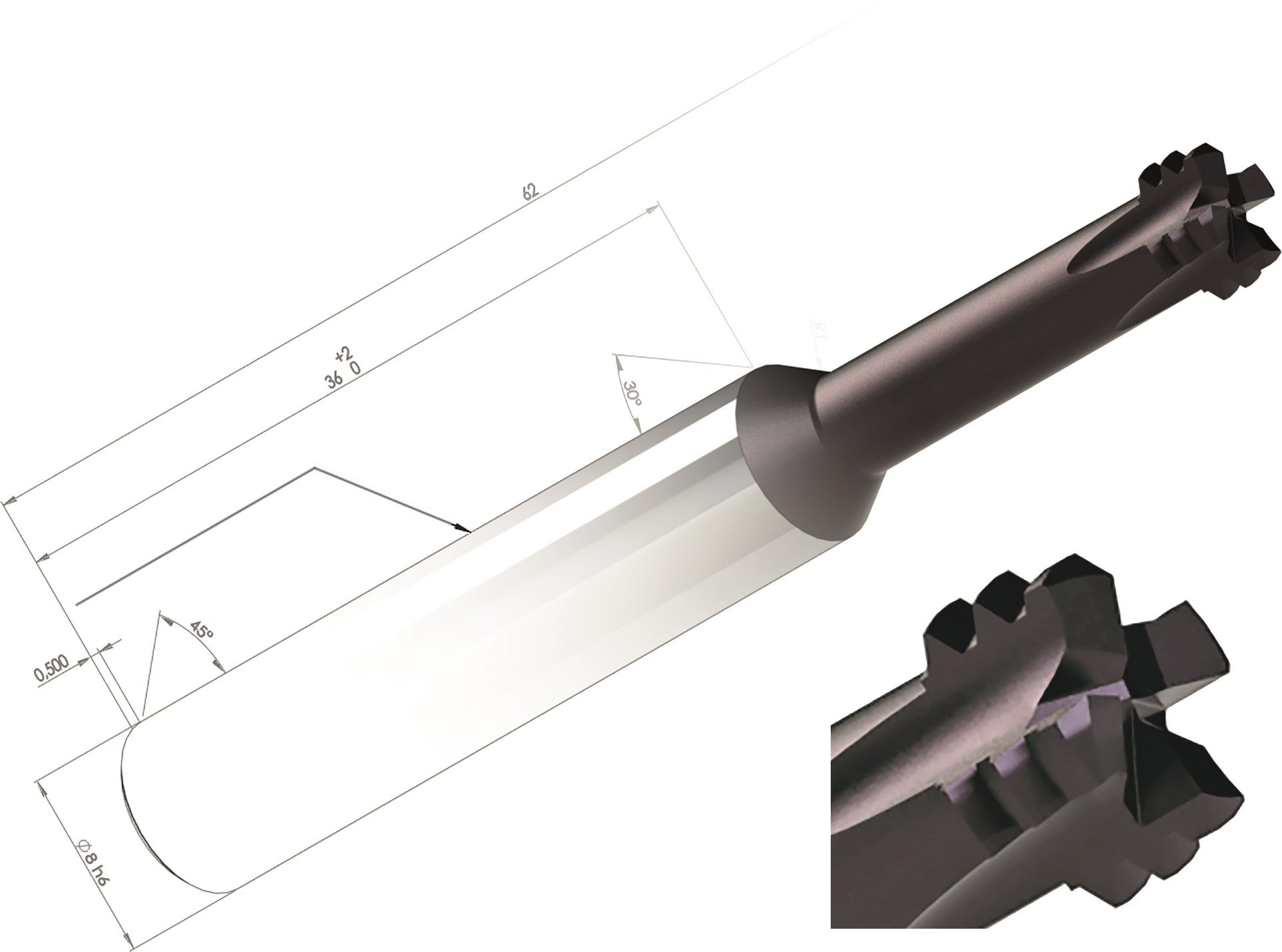

A central further development at

JBO is the circular bore thread milling cutter. It was specially designed

for machining in die and mould making, among other things for machining

hardened and tempered steel materials with a hardness >=54 to 66 HRC.

Further areas of application are the machining of cast materials,

titanium alloys and non-ferrous metals as well as unhardened steels.

Finely ground flutes, an optimised cutting geometry as well as a new hard

metal and a new coating contribute to a uniform wear behaviour with a

longer tool life.

The tools are available in the dimensions M3-M16 as well as M8x0.75 and

M10x1. In the standard programme, thread depths of up to 2.5xD can be

realised.

|

|

|

Pic.1: Schematic injection mould Pic.2: BGFS

You

can find a video about this tool system on our YouTube channel under the

following link:

You can find the general flyer about these tools on our homepage under the

following link:

https://www.johs-boss.de/images/service/downloads/prospekte/VHM_Zirkularbohrgewindefraeser_02_2021.pdf

We

would be happy to present this tool system to you in detail in person.